Build Smarter: How Aftermarket Construction Parts Can Enhance Your Bottom Line

Build Smarter: How Aftermarket Construction Parts Can Enhance Your Bottom Line

Blog Article

Elevate Your Fleet's Possible: The Worth of Aftermarket Components in Heavy Equipment

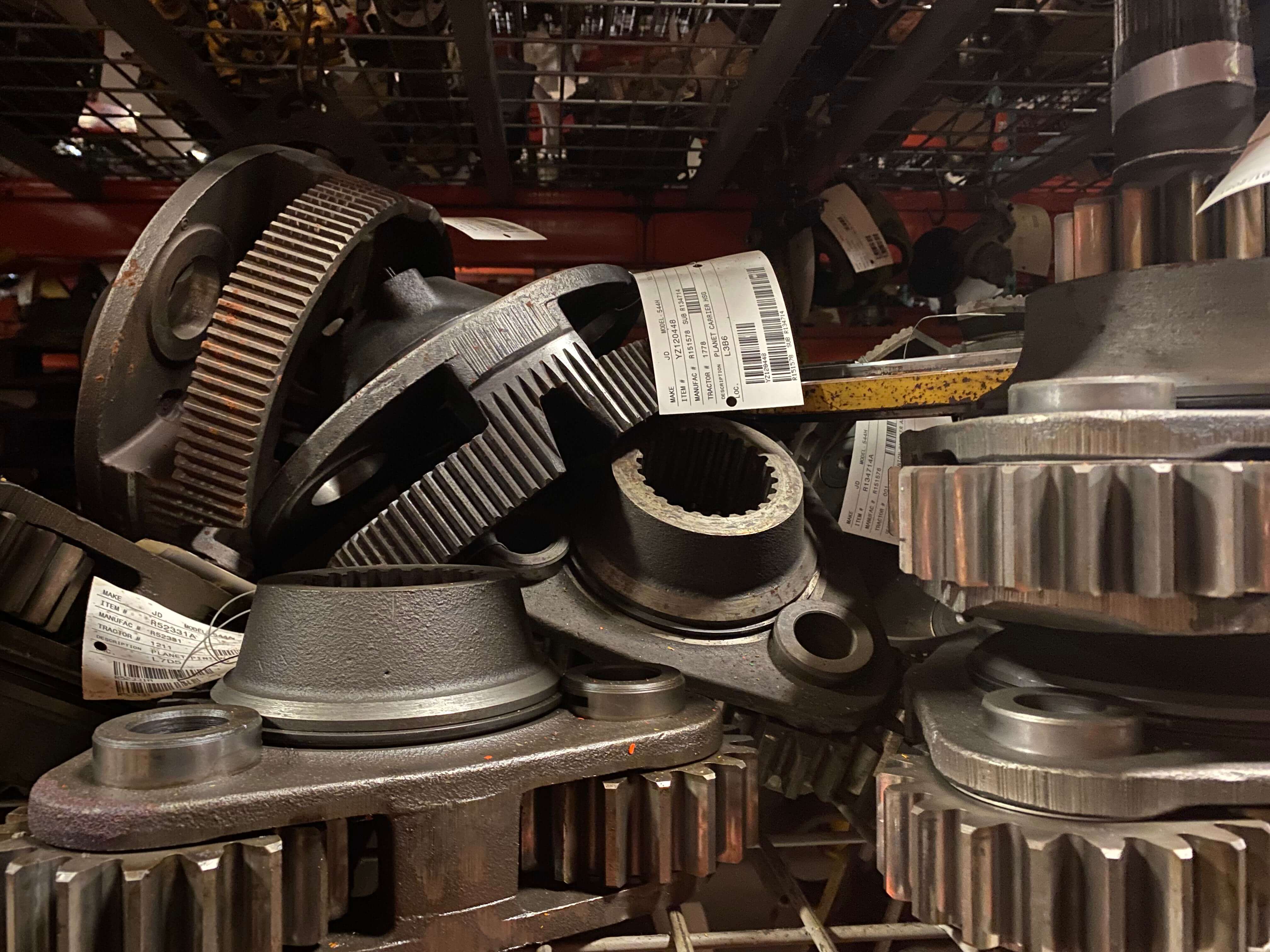

In the world of hefty machinery procedures, the utilization of aftermarket components stands as a tactical selection that can exceptionally affect the efficiency and durability of your fleet. Think about a situation where your machinery operates perfectly, prices are reduced, and efficiency is optimized - aftermarket parts play a pivotal role in achieving these outcomes.

Benefits of Making Use Of Aftermarket Parts

One of the vital benefits of aftermarket parts is the raised availability and variety they offer. Because aftermarket makers create a large range of components for various machinery brand names, it is less complicated for businesses to discover the details parts they require without experiencing delays often connected with ordering OEM parts. This access also cultivates competition, which can drive down rates and bring about additional cost financial savings for firms.

Moreover, aftermarket parts are recognized for their high quality and efficiency. Several aftermarket manufacturers spend in research and development to guarantee their components fulfill or surpass sector standards. This dedication to excellence cause trustworthy elements that can improve the total effectiveness and efficiency of heavy equipment, making aftermarket parts a beneficial option for businesses seeking to optimize their procedures.

Cost-Effectiveness and Performance

The implementation of aftermarket parts in hefty equipment highlights the extremely important significance of cost-effectiveness and performance in modern industrial procedures. Using aftermarket parts can significantly lower upkeep and repair work prices compared to OEM parts, offering a cost-effective service for fleet administration. These components are frequently extra competitively valued without jeopardizing on top quality, permitting companies to maximize their budget plans without giving up efficiency.

Furthermore, aftermarket parts are conveniently offered, reducing downtime for machinery maintenance and repair. aftermarket construction parts. This accessibility translates to boosted effectiveness in procedures, as devices can be swiftly serviced and returned into service. This structured process not just conserves time however likewise increases general productivity, making certain that jobs remain on schedule and within budget plan

Enhancing Efficiency With Aftermarket Components

With the shown cost-effectiveness and performance benefits of aftermarket components in hefty machinery operations, the emphasis currently shifts in the direction of exploring just how these parts can even more boost total efficiency. Aftermarket elements offer a critical advantage by supplying personalization choices tailored to certain needs. By incorporating high-performance aftermarket parts, hefty equipment drivers can optimize their tools to supply premium cause numerous applications.

Enhancing efficiency with aftermarket components entails updating important parts such as engines, transmissions, hydraulic systems, and braking systems. These upgrades can cause enhanced power result, boosted longevity, enhanced rate control, and far better general machine responsiveness. In addition, aftermarket elements useful reference commonly use innovative innovations and products, contributing to improved integrity and durability of the equipment.

Additionally, aftermarket components can allow heavy machinery to operate extra effectively, decreasing downtime and maintenance costs. Boosted efficiency converts to higher productivity degrees and raised profitability for companies depending on heavy equipment operations. By purchasing top quality aftermarket components, firms can boost their fleet's abilities and stay affordable in the ever-evolving hefty machinery industry.

Taking Full Advantage Of Machinery Lifespan

To prolong the operational longevity of hefty machinery, strategic maintenance practices and aggressive surveillance play essential roles in making the most of machinery lifespan. Additionally, sticking to supplier standards for maintenance and service intervals is vital in making sure optimal performance and expanding the lifespan of heavy machinery.

Proactive surveillance through the usage of innovative telematics systems can provide real-time data on equipment health and wellness and efficiency. Keeping track of parameters such as engine hours, fuel intake, and running temperature levels can assist identify patterns or inconsistencies that might suggest underlying issues. By leveraging modern technology to track and assess equipment information, operators can make enlightened choices to address issues quickly, inevitably extending the lifespan of hefty machinery and maximizing operational effectiveness.

Affordable Edge With Aftermarket Solutions

Exploring the advantages of aftermarket options can significantly improve a firm's competitive side in the heavy machinery market. Aftermarket providers usually have readily available parts, minimizing downtime for machinery and boosting general functional effectiveness.

Additionally, aftermarket remedies make it possible for site link firms to customize their offerings to fulfill the unique requirements of different customers. This flexibility enables organizations to give personalized solutions, causing enhanced customer fulfillment and loyalty. Furthermore, aftermarket components are typically extra cost effective than OEM components, allowing firms to use affordable pricing while keeping top notch standards.

Moreover, aftermarket options can also add to sustainability initiatives by promoting the reuse and recycling of equipment components. Firms that prioritize environmentally friendly practices with aftermarket options can bring in ecologically aware customers, even more boosting their competitive edge in the hefty machinery here market.

Final Thought

In final thought, aftermarket parts provide numerous advantages for heavy equipment fleets. Generally, incorporating aftermarket services right into fleet maintenance practices can boost the possibility of heavy equipment and add to increased effectiveness and earnings.

In the world of heavy machinery procedures, the application of aftermarket parts stands as a tactical choice that can profoundly influence the efficiency and durability of your fleet.Using aftermarket parts in heavy equipment can offer both expense financial savings and enhanced efficiency compared to using original devices manufacturer (OEM) components. Since aftermarket makers generate a wide range of parts for various equipment brands, it is less complicated for companies to locate the details components they need without experiencing hold-ups typically connected with ordering OEM parts.The application of aftermarket components in hefty equipment underscores the vital relevance of cost-effectiveness and efficiency in contemporary industrial operations.With the demonstrated cost-effectiveness and effectiveness benefits of aftermarket parts in heavy machinery procedures, the focus now moves towards discovering just how these elements can further enhance total efficiency.

Report this page